Amongst the Top 3D Printing Companies in Dubai and the UAE

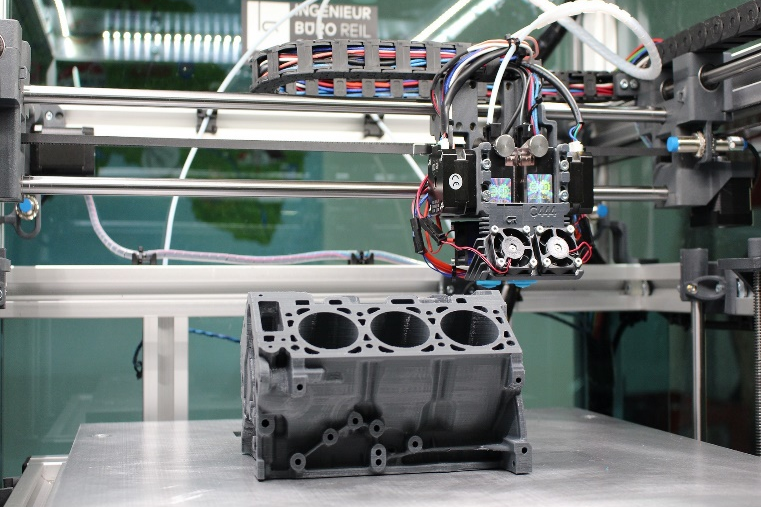

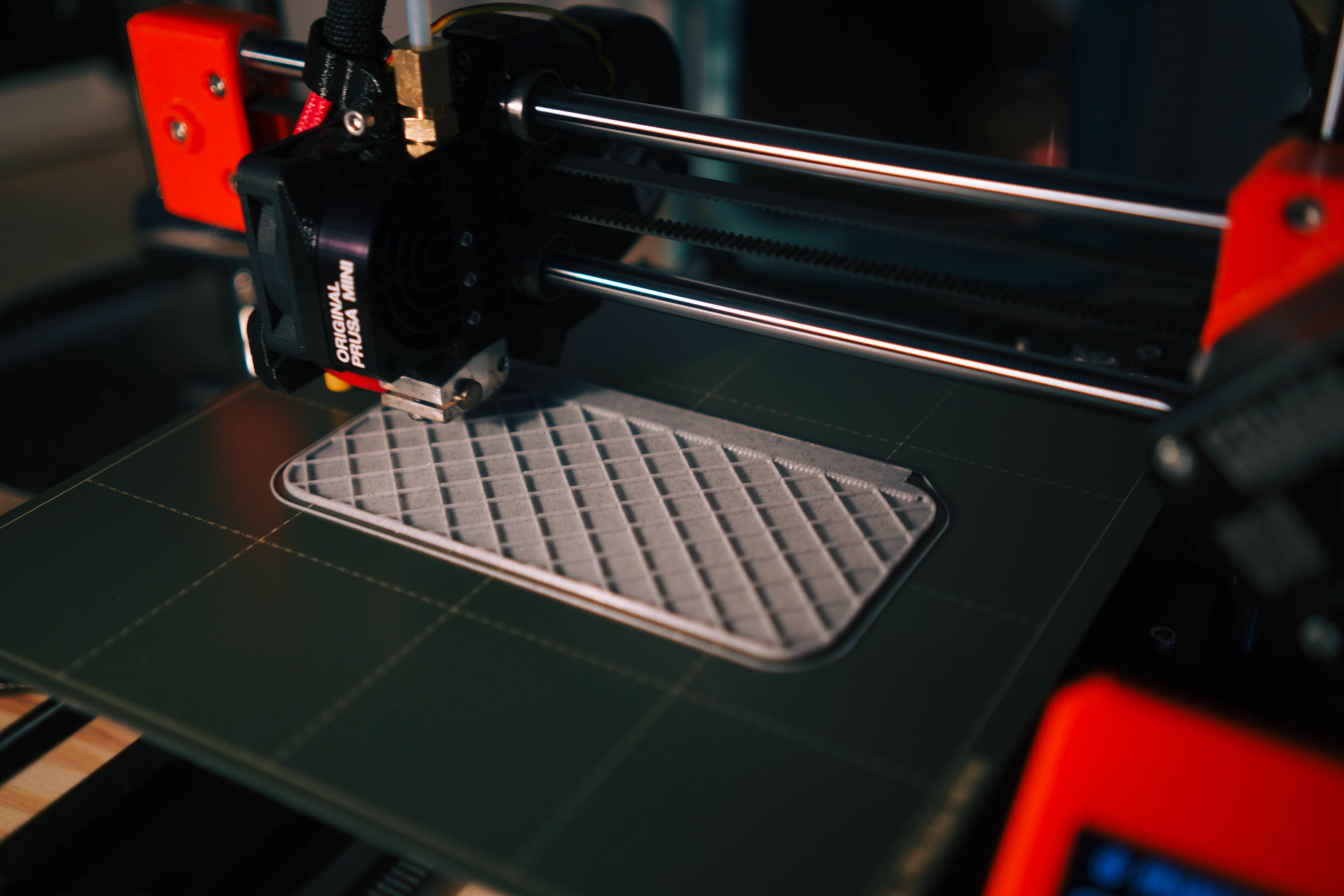

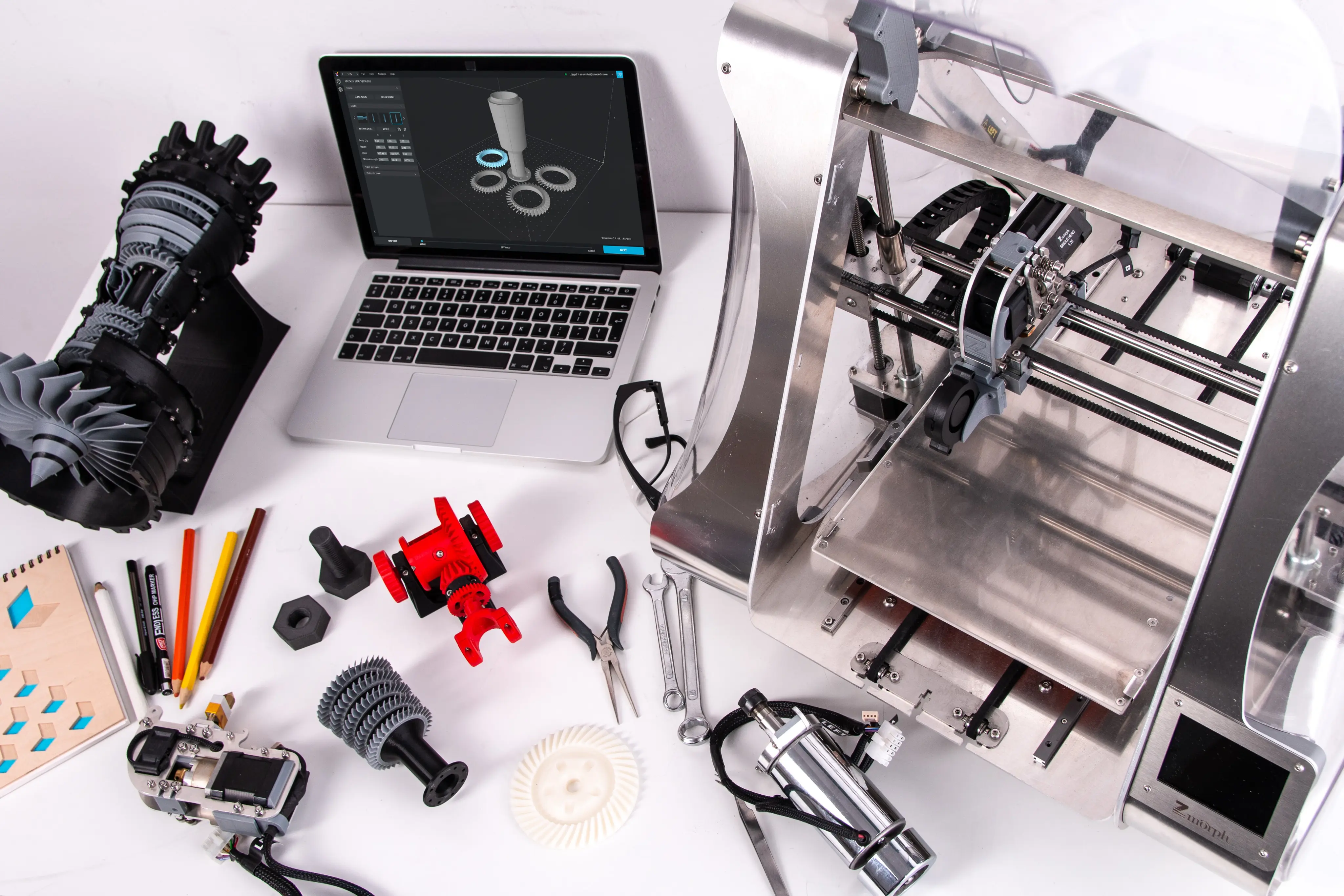

We, at Rapid 3D, are dedicated to providing the highest quality 3D services to several industries including Manufacturing, Automotive, Architecture, Visual Merchandising, Art & Interior. We use the latest technology equipment and machineries to ensure the best possible output.

Our team of highly qualified and experienced engineers provides you with the most effective solution to your problems. Our R&D department is constantly improving current technology and developing methods to make it more efficient.

Industries We Serve :

Art and Interior

Art and Interior Manufacturing

Manufacturing Product Development

Product Development Visual Merchandising

Visual Merchandising

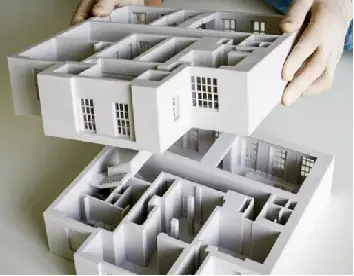

Architecture

Architecture Consumer Products

Consumer Products Jewelery & Fashion

Jewelery & Fashion Medical

Medical